We’re not afraid of hard work. We roll up our sleeves, and we dig in. Built on a strong legacy of successful projects, we offer the best solutions, service, and quality at every stage of the project, from breaking new ground to commissioning and ongoing site .

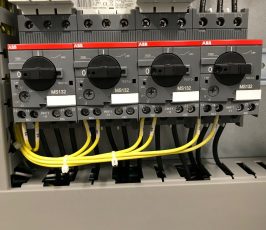

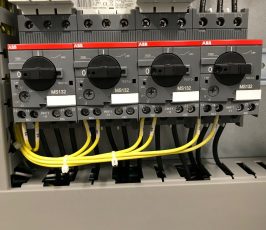

Control Building Fabrication

More

St. Lawrence/Fermeuse Wind Farm

More

Condition Assessment and Rebuild Services of Pipe Elevator Feeder and Bridge Unit Extensions for Hibernia Platform

More

Controls and Automation Onboard the M.V. Calvert

More

Restoration of T2 Transformer (230/16KV, 170MVA) in Holyrood

More

Control System Upgrade for Hibernia Platform Blow Out Preventer (“BOP”) Cranes

More

Blue Beach Marine Terminal – Diesel Genset & Electrical Distribution

More

Soldiers Pond Synchronous Condenser Facility Electrical & Mechanical

More

West Side Modernization Project

More

Voisey’s Bay Mine Expansion – Design and Supply of Fuel Pumphouses

More

Dam Replacement at Lock 38, along Parks Canada’s Trent-Severn Waterway National Historic Site

More

Petty Harbour Penstock

More

L.F. Wade International Airport Bermuda, BDA Fuel Farm

More

Deer Lake Power Transformer Repair, Modification, Oil Fill & Testing

More

Refrigeration Plant Upgrade

More

Talbot Canal – Parks Canada’s Trent-Severn Waterway

More

Ottawa Light-Rail Transit System – Phase 2 Trillium Line

More

Crane Refit Onboard The CCGS Amundsen For The Canadian Coast Guard

More

Subsea Rigid Spool Work

More

West Aquarius Support

More

Greenhouse Irrigation Control System

More

PETTY HARBOR / LONG POND WATER TREATMENT PLANT

More

Upgrade for the BOP Handling Cranes for Hibernia Platform

More